Matla a phahamengpina ea bolt le nutlikopano li bapala karolo ea bohlokoa ho boloka botsitso le ts'ebetso ea likariki tsa ka tlas'a lihahabi. Meepong ea koporo ea Chile, ho latela litsamaiso tsa bolt le linate, hammoho lekarolo ea bolt le nutmetsoako, mamella khatello ea maikutlo e feteletseng, hangata e hlokang ho nkeloa sebaka ka lihora tse ling le tse ling tse 800-1,200. Ho feta moo,lema bolt le nateLitharollo li bohlokoa bakeng sa lits'ebetso tse fapaneng tsa mochini o boima. European Machinery Directive 2023 e laela tlhahlobo ea ultrasonic ho ntlafatsa polokeho, e totobatsa tlhoko ea bohlokoa ea li-fasteners tse tšepahalang ts'ebetsong e boima.

Lintlha tsa bohlokoa

- Liboutu tse matla le linateli bohlokoa bakeng sa likoloi tse tsamaeang ka tlas'a metsi. Ba boloka litsela, ba thusa mechine hore e sebetse hantle libakeng tse thata.

- Ho hlahloba liboutu le linate hangata ho ka bona tšenyo kapele. Ho lokisa mathata esale pele ho qoba litokiso tse bitsang chelete e ngata 'me ho boloka thepa e sebetsa hantle.

- Ho sebelisalisebelisoa tse matla bakeng sa liboutu'me linate li theola litšenyehelo tsa ho lokisa. Likarolo tse thata li nka nako e telele, kahoo u li nkela sebaka hangata, ho boloka chelete le nako.

Ho utloisisa li-Undercarriages tsa Crawler

Kakaretso ea Crawler Undercarriages

Likoloi tse ka tlas'a Crawler li theha motheo oa mochini o boima, o nolofalletsang ho tsamaea hantle libakeng tse matsutla-tsutla. Litsamaiso tsena li na le lipina, li-roller, le likarolo tse ling tse etselitsoeng ho aba boima ka ho lekana le ho boloka botsitso. Likhatelo-pele tsa morao-rao 'marakeng oa likoloi tse tsamaeang ka tlas'a likoloi li totobatsa ho amoheloa ha lisebelisoa tse bobebe tse kang tšepe ea matla a phahameng le li-polymers tse tsoetseng pele. Litlhahiso tsena li ntlafatsa ho tšoarella le ho sebetsa hantle ha mafura, ho lumella mechine ho sebetsa ka katleho libakeng tse thata. Ntle le moo, ho kopanngoa ha li-sensor tsa IoT bakeng sa ho lekola nako ea 'nete ho bonts'a phetoho e lebisang mecheng e bohlale, e sebetsang hantle haholoanyane. Mokhoa ona o bonahala haholo libakeng tse ntseng li tsoela pele joalo ka Asia-Pacific, moo matsete a litšebeletso a tsamaisang tlhokahalo ea lisebelisoa tse tšepahalang.

Likarolo Tsa Bohlokoa le Mesebetsi ea Tsona

Likariki tsa Crawler li itšetlehile ka likarolo tse 'maloa tsa bohlokoa ho netefatsa ts'ebetso e nepahetseng:

- Lipina: Tsena li fana ka ts'ehetso le ts'ehetso, tse nolofalletsang mochini ho feta libakeng tse sa tšoaneng.

- Lirolara le li-Idlers: Tsena li tataisa le ho ts'ehetsa lipina, ho netefatsa ts'ebetso e bonolo le ho tsamaisana hantle.

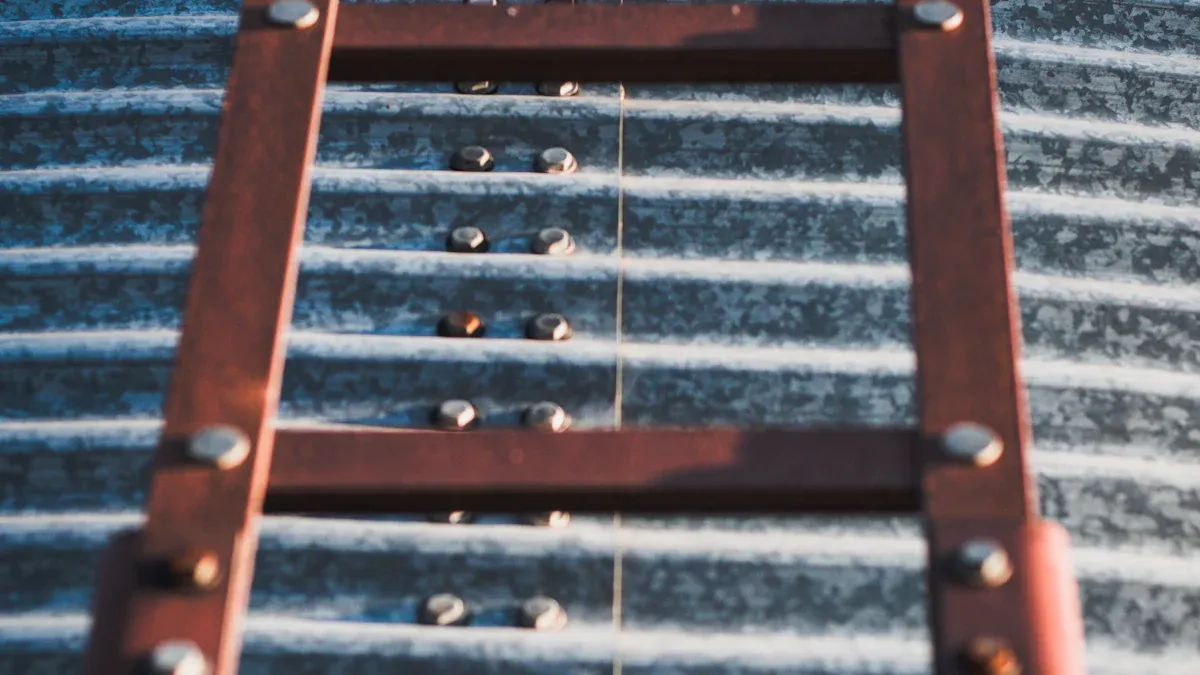

- Latela Likopano tsa Bolt le Nut: Tsena li sireletsa litsela ho ea ka tlas'a koloi, li boloka botšepehi ba mohaho tlas'a meroalo e boima.

- Khanna Sprockets: Matla ana a ho fetisa ho tloha enjene ho ea ho litsela, ho tsamaisa mochine pele.

Mekhoa ea ho itloaetsa indastering e hatisa litharollo tse lokiselitsoeng ho fihlela litlhoko tse ikhethileng tsa ts'ebetso. Mohlala, tlhahlobo e khethehileng ea ho ikamahanya le maemo tikolohong e netefatsa hore likarolo li sebetsa ka ts'epahalo mochesong o feteletseng kapa maemong a senyang. Mekhoa ea ho hlahloba le ea ho lekola, joalo ka tlhahlobo ea morao-rao le netefatso ea ts'ebetso ea tiiso, e matlafatsa le ho feta ho tšoarella le ho sebetsa hantle ha litsamaiso tsena. Ka ho latela litekanyetso tsa indasteri joalo ka ISO 6014, bahlahisi ba netefatsa hore likariki tsa ka tlas'a lihahabi li kopana le litekanyetso tse matla tsa ts'ebetso.

Karolo ea Track Bolt le Nut ho Crawler Undercarriages

Ho netefatsa Botsitso le Botšepehi ba Sebopeho

Latela liboutu le linatesebetsa joalo ka mokokotlo oa likariki tsa ka tlas'a lihahabi. Likarolo tsena li sireletsa lipina ho foreimi ea undercarriage, ho thibela ho falla nakong ea ts'ebetso. Mechini e boima hangata e sebetsa libakeng tseo ho tsona libaka tse sa leka-lekaneng le matla a matla a matla a phephetsang botsitso ba sebopeho. Ntle le li-fasteners tse tšepahalang, lipina li ne li ka hlephisa kapa tsa haroha, tsa sitisa bokhoni ba mochini ho sebetsa ka mokhoa o sireletsehileng le ka katleho.

Baetsi ba rala liboutu le linate ho mamella khatello e matla le ho thothomela. Lisebelisoa tse matla, tse kang tšepe ea alloy, li netefatsa hore li-fasteners tsena li boloka botšepehi tlas'a meroalo e boima. Boenjineri bo nepahetseng bo ntlafatsa ts'ebetso ea bona, bo ba lumella ho hanela ho khathala le ho senyeha ha nako.

Keletso:Ho hlahlojoa khafetsa ha liboutu tsa pina le linate ho ka thusa ho tseba matšoao a pele a ho senyeha kapa ho senyeha, ho netefatsa hore ho nkeloa sebaka ka nako le ho thibela ho senyeha ho hoholo.

Tlatsetso ho Phatlalatso ea Meroalo le ho tsamaisana

Liboutu le linate li bapala karolo ea bohlokoa ho arola boima ba 'mele ka ho lekana ho pholletsa le kariki. Kabo e nepahetseng ea mojaro e fokotsa khatello ea maikutlo ho likarolo tsa motho ka mong, ho lelefatsa bophelo ba bona le ho fokotsa kotsi ea ho hloleha ha mochini. Ka ho boloka lipina ka tieo, li-fasteners tsena li netefatsa hore mochini o boloka tlhophiso e nepahetseng nakong ea ts'ebetso.

Lipina tse sa tsamaellaneng hantle li ka lebisa ho se sebetseng hantle, ho fokotsa ts'ebetso le ho eketseha ha tšebeliso ea mafura. Track liboutu le linate thibela litaba tse joalo ka ho boloka lipina sebakeng seo ba se rerileng. Tokiso ena e bohlokoa haholo lits'ebetsong tse kang tsa merafo le kaho, moo mochini o tlamehang ho tsamaea libakeng tse thata ha o ntse o jara meroalo e boima.

Mokhoa o hlokometsoeng hantle oa bolt le linate o thusa ho sebetsa hantle le ho ntlafatsa ts'ebetso. Basebelisi ba ka itšetleha ka mechini ea bona ho sebetsana le mesebetsi e boima ntle le litšitiso, ho ntlafatsa tlhahiso le polokeho sebakeng sa mosebetsi.

Bohlokoa ba Lisebelisoa tse Matla a Phahameng ho Track Bolts le Nuts

Ho Khanyetso Meroalo e Boima le Khatello ea Maikutlo

Lisebelisoa tse matla hahololiboutu le linate li bohlokoa bakeng sa ho sebetsana le meroalo e meholohali le likhatello tse bang teng ts'ebetsong ea mochini o boima. Li-fasteners tsena li tlameha ho mamella khatello e sa khaotseng ea libaka tse sa tšoaneng, ho thothomela le boima ba thepa ka boeona. Liteko tsa laboratori li tiisa bokhoni ba tsona ba ho hanela matla a joalo ka litlhahlobo tse matla.

| Mofuta oa Teko | Tlhaloso |

|---|---|

| Teko ea Mechini | E kenyelletsa tlhahlobo ea boima ba bopaki, tlhahlobo ea ho tiea, le tlhahlobo ea boima ba 'mele (Rockwell, Brinell, jj.) |

| Teko ea Metallurgical | E kenyelletsa tlhahlobo ea bothata ba microhardness, liteko tsa microstructural, le lipatlisiso tsa ho hloleha ha metallurgical |

| Tlhahlobo ea Lik'hemik'hale | E kenyelletsa tlhahlobo ea ICP/OES le Spark OES ho lekola sebopeho sa thepa le thepa |

Liteko tsena li tiisa seolatela liboutu le linatekopana le maemo a indasteri bakeng sa matla le ho tšepahala. Teko ea khafetsa ea li-fasteners le lisebelisoa tse tala li netefatsa hore li loketse tikoloho e batloang haholo. Teko ea bolt e boetse e netefatsa hore likarolo tsena li ka mamella mojaro oa tsona o khethiloeng le ho sebetsa ka katleho tlas'a khatello ea ts'ebetso.

Ho tšoarella libakeng tse thata

Liboutu le linate li tlameha ho sebetsa ka mokhoa o ts'epahalang maemong a feteletseng, ho kenyeletsoa mocheso o phahameng, tikoloho e senyang, le ho pepesehela matla a kantle khafetsa. Liteko tsa masimong le litlhahlobo tsa tikoloho li bonts'a ho tšoarella ha tsona maemong a joalo.

- Teko e teng ea torque e lekola hore na li-fasteners li hanela ho lokoloha joang ka lebaka la ho thothomela le matla a kantle.

- Teko ena e bohlokoa liindastering tse kang nyutlelie, sepakapaka, le tsa leoatleng, moo botšepehi bo thibelang ho hlōleha ha koluoa.

- Liphetho tse tsoang litekong tsena li netefatsa hore liboutu le linate li fihlella maemo a tlase bakeng sa ts'ebeliso e reriloeng, ho fokotsa likoli le ho matlafatsa ts'ebetso e tšoarellang.

Ka ho hanela ho roala le ho lokoloha, lisebelisoa tse matla haholo li eketsa nako ea bophelo ea likopano tsa pina le linate. Ho tšoarella hona ho fokotsa litlhoko tsa tlhokomelo le ho netefatsa hore mechini e sebetsa ka mokhoa o sireletsehileng le ka katleho libakeng tse thata.

Melemo ea Li-Bolts le Linate tse Matla a Phahameng

Ntlafatso ea Tšireletseho le Tšepahala

Liboutu le linate tse matla haholoho matlafatsa polokeho le botshepehi ba dikariki tse ka tlase tsa batho ba hahabang. Likarolo tsena li netefatsa hore lipina li lula li tiisitsoe ka mokhoa o sireletsehileng, esita le tlas'a maemo a feteletseng a ts'ebetso. Ka ho thibela ho falla ha pina kapa ho arohana, ba fokotsa kotsi ea likotsi le ho hlōleha ha lisebelisoa.

Tšebeliso ea lisebelisoa tse tsoetseng pele, tse kang tšepe ea alloy, e fana ka khanyetso e ikhethang ea khatello ea maikutlo le ho thothomela. Ho tšoarella hona ho netefatsa hore li-fasteners li boloka botšepehi ha nako e ntse e ea, esita le libakeng tse nang le tšusumetso e phahameng joalo ka libaka tsa kaho kapa mesebetsi ea merafo. Basebelisi ba ka tšepa hore mochini oa bona o tla sebetsa ka mokhoa o ts'oanang, ba tseba hore liboutu tsa pina le linate li etselitsoe ho sebetsana le mesebetsi e boima.

Hlokomela:Ho hlahlojoa khafetsa le ho hlahloba torque ho tsoela pele ho ntlafatsa polokeho ka ho tseba mathata a ka bang teng pele a fetoha liphoso tse kholo.

Nako e telele ea Bophelo ea Likarolo tsa Undercarriage

Li-bolts le linate tse matla haholo li kenya letsoho bophelong bo atolositsoeng ba likarolo tsa undercarriage. Ka ho tiisa liporo, ba fokotsa ho sisinyeha ho sa hlokahaleng le ho roala likarolo tse haufi, joalo ka lirolara, li-idlers le li-sprockets. Botsitso bona bo fokotsa khatello ea likarolo ka bomong, e ba lumella ho sebetsa ka katleho nako e telele.

Kabo e nepahetseng ea mojaro, e tsamaisoang ke li-fasteners tsena, le eona e phetha karolo ea bohlokoa ho baballeng bokantle ba koloi. Kabo e sa leka-lekaneng ea boima ba 'mele e ka lebisa ho taboha le ho taboha pele ho nako, empa liboutu le linate tsa boleng bo holimo li netefatsa hore mojaro o phatlalalitsoe ka ho lekana ho pholletsa le sistimi. Ho leka-lekana hona ha ho ntlafatse ts'ebetso feela empa hape ho liehisa tlhokahalo ea ho nkela sebaka se bitsang chelete e ngata.

Hangata bahlahisi ba khothaletsa ho sebelisa li-fasteners tse finyellang litekanyetso tsa indasteri ho eketsa nako e telele ea kopano eohle ea undercarriage. Ho tsetela holikarolo tse matla haholoqetellong e boloka nako le lisebelisoa ka ho fokotsa makhetlo a ho lokisa.

Litšenyehelo tse Tlaase tsa Tlhokomelo le Nako ea ho Pholosa

Ho sebelisa li-bolts le linate tse matla haholo ho ka fokotsa litšenyehelo tsa tlhokomelo le ho fokotsa nako ea ho theoha. Li-fasteners tsena li etselitsoe ho mamella maemo a thata, ho fokotsa monyetla oa ho hloleha ho sa lebelloang. Ka lebaka leo, basebetsi ba qeta nako e nyane ba sebetsana le litaba tsa mochini le nako e ngata ba tsepamisitse maikutlo mesebetsing e hlahisang litholoana.

Ho tšoarella ha likarolo tsena ho boetse ho fetolela ho fokotseha ho fokolang, e leng ho fokotsang litšenyehelo tse akaretsang tsa tlhokomelo. Bakeng sa liindasteri tse kang tsa merafo le kaho, moo ho fokotseha ha lisebelisoa ho ka lebisang tahlehelong e kholo ea lichelete, botšepehi bona ke ba bohlokoa haholo.

Keletso:Ho kenya ts'ebetsong kemiso ea tlhokomelo e sebetsang e kenyelletsang tlhahlobo ea kamehla ea liboutu le linate ho ka fokotsa nako ea ho theoha le ho netefatsa ts'ebetso e nepahetseng.

Ka ho khetha li-fasteners tse matla haholo, likhoebo li ka fumana tekano lipakeng tsa ts'ebetso ea ts'ebetso le ho boloka litšenyehelo. Peeletso ena ha e ntlafatse ts'ebetso ea likariki tsa ka tlase feela empa hape e ts'ehetsa phaello ea nako e telele.

Ho khetha le ho boloka pina ea Bolts le Nuts

Lintlha Tseo U Lokelang ho li Nahana Ha U Khetha Bolts le Linate tse Matla a Phahameng

Ho bohlokoa ho khetha liboutu le linate tse matla haholo bakeng sa ho netefatsa ts'ebetso le polokeho ea likariki tsa ka tlas'a lihahabi. Mekhoa e mengata ea tekheniki le maemo a indasteri a tataisa ts'ebetso ena:

- Khetho ea Lintho: Khetha lisebelisoa tse kang tšepe, tšepe e sa hloekang, kapa tšepe ea alloy ho finyellamatla a phahameng a tsitsipanole durability.

- Likhetho tsa ho roala: Sebelisa liphahlo tse joalo ka zinc plating kapa galvanizing ho matlafatsa khanyetso ea kutu, haholo maemong a thata.

- Boholo le Mofuta: Netefatsa hore mofuta oa fastener le boholo bo tsamaellana le ts'ebeliso, ho supa maemo a fastening a ASTM bakeng sa ho nepahala.

- Lintlha tsa Bohlokoa tsa Ts'ebetso: Nahana ka bophara ba bolt, tekanyo ea pretension, le matla a ho tsitsa, kaha tsena li ama ts'ebetso ea ho kuta le boima ba mojaro haholo.

- Maemo a Tikoloho: Lekola lintlha tse kang mocheso, khatello, le ho bola ho netefatsa hore li-fasteners li khona ho mamella mathata a ts'ebetso.

Mekhoa e nepahetseng ea ho kenya le eona e phetha karolo ea bohlokoa ho holiseng katleho ea liboutu tsa pina le likopano tsa linate. Ka mohlala, ho sebelisa linate tse peli kapa ho tiisa selemo ho ka thusa ho laola tahlehelo ea boikaketsi, ho ntlafatsa botšepehi ba nako e telele.

Malebela a Tlhokomelo bakeng sa Ts'ebetso e Ntle

Mekhoa e metle ea tlhokomelo e bohlokoa bakeng sa ho ntlafatsa ts'ebetso le nako ea bophelo ea liboutu le linate. Ho hlahlojoa khafetsa le mehato e potlakileng ho ka thibela ho hloleha ho bitsang chelete e ngata. Litlhahiso tsa bohlokoa tsa tlhokomelo li kenyelletsa:

- Kemiso ea Litlhahlobo tsa Kamehla: Hlahloba li-fasteners bakeng sa matšoao a ho felloa ke matla, ho bola, kapa ho hlephisa.

- Boloka Lirekoto tse qaqileng: Boloka lits'ebetso tsa tokiso ho latela mekhoa ea ts'ebetso le ho tseba mathata a hlahang khafetsa.

- Matlafatsa Basebelisi: Koetlisa basebelisi ho lemoha matšoao a pele a ho hloleha ha lebelo, joalo ka ho thothomela ho sa tloaelehang kapa ho se tsamaisane hantle.

- Sebelisa Theknoloji: Sebelisa software ea ho lokisa likepe kapa li-analytics tsa CMMS ho beha leihlo ts'ebetso ea fastener le ho lokisa linako tsa tokiso ka nepo.

- Tsetela ho Lisebelisoa tsa Bohlale: Sebelisa li-wrenches tsa torque le lisebelisoa tse ling tse nepahetseng ho netefatsa ho tiisa ka mokhoa o nepahetseng nakong ea ho kenya le ho lokisa.

Mekhoa e thibelang ea tlhokomelo, e kang Asset Performance Management (APM), e hatisa pokello ea lintlha le tlhahlobo ea esale pele. Mekhoa ena e thusa ho tseba ho se sebetse hantle le ho ntlafatsa linako tsa tlhokomelo, ho netefatsa hore likariki tsa ka tlas'a maoto li sebetsa ka mokhoa o sireletsehileng le ka katleho.

Keletso: Li-washer tsa undercarriage tse ikemetseng li ka fokotsa nako ea tlhokomelo le ho ntlafatsa tlhahiso ka ho felisa mesebetsi ea matsoho ea ho hloekisa.

Liboutu le linate tse matla haholo li bohlokoa bakeng sa ho netefatsa polokeho, ho tšoarella le ho sebetsa hantle ha likariki tsa ka tlas'a lihahabi. Karolo ea bona ea ho boloka botšepehi ba sebopeho le ho fokotsa litšenyehelo tsa tlhokomelo e ke ke ea fetisoa.

Ho tsetela holi-fasteners tsa boleng ba premiume ntlafatsa ts'ebetso ea lisebelisoa le ho fokotsa nako ea ho theoha, e fanang ka poloko ea nako e telele ea litšenyehelo le ts'epahalo ea ts'ebetso. Khetha ka bohlale bakeng sa liphello tse tšoarellang.

LBH

Ke eng e etsang hore liboutu le linate tse matla haholo li fapane le li-fasteners tse tloaelehileng?

Liboutu le linate tse matla haholosebelisa lisebelisoa tse tsoetseng pele joalo ka tšepe ea alloy. Ba hanela meroalo e boima, ho thothomela, le khatello ea tikoloho, ho netefatsa ho tšoarella le ho ts'epahala lits'ebetsong tse hlokang.

Liboutu le linate li lokela ho hlahlojoa hangata hakae?

Hlahlobalatela liboutu le linatelihora tse ling le tse ling tse 500-1,000 tsa ts'ebetso. Ho hlahloba khafetsa ho thusa ho tseba ho felloa ke matla, ho bola, kapa ho hlepha, ho thibela ho hloleha ho sa lebelloang le nako e theko e boima.

Na liboutu le linate tse matla haholo li ka fokotsa litšenyehelo tsa tlhokomelo?

E, ho tšoarella ha tsona ho fokotsa ho nkeloa sebaka le ho lokisoa. Ho tšepahala hona ho fokotsa litšenyehelo tsa tlhokomelo le litšitiso tsa ts'ebetso, haholo indastering e kang ea merafo le ea kaho.

Nako ea poso: Apr-27-2025