Tlhahiso ea Bolt e Matla a Phahamenge sebelisa mokhoa o tsoetseng pele ho eketsa litekanyetso tsa ho hlaphoheloa ha thepa ho tloha ho 31.3% ho ea ho 80.3%, ha matla a ho tiea le ho thatafala ho ntlafala ka hoo e ka bang 50%.

| Mofuta oa Ts'ebetso | Sekhahla sa Pholoso ea Lintho (%) |

|---|---|

| Shaft e Kenyellelitsoeng ka Mochini | 31.3 |

| Shaft e Kenyellelitsoeng | 80.3 |

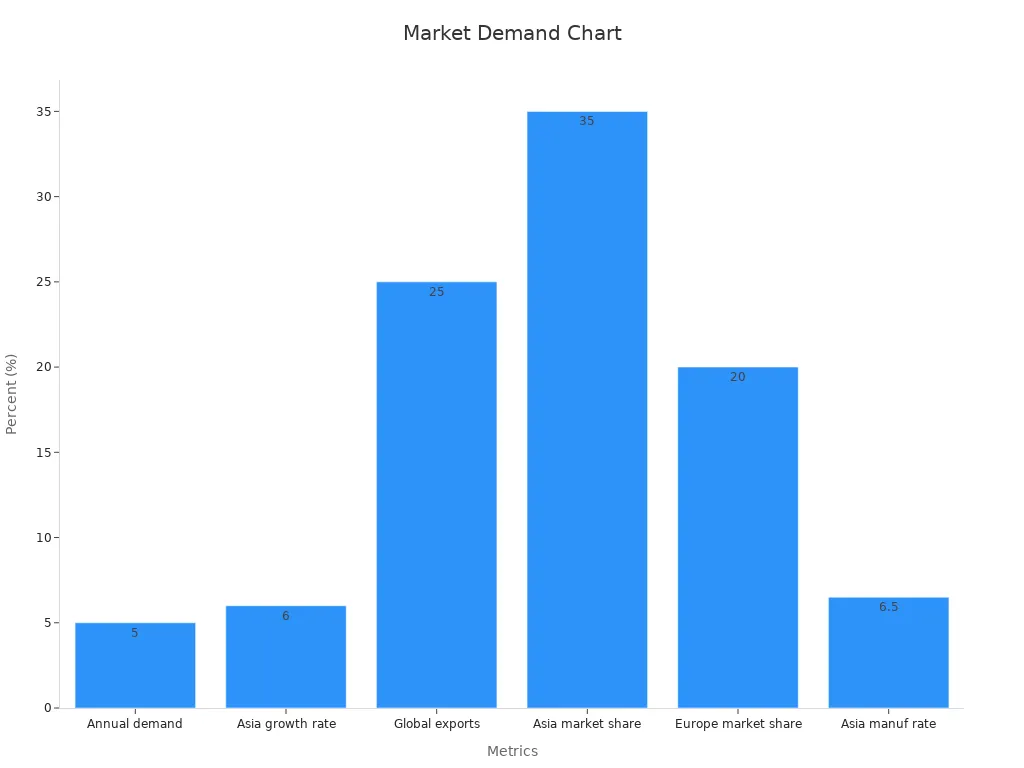

Bolt e matla hahololihlahisoa tse kangliboutu tsa mohoma tse matla haholo, Liboutu tsa lieta tsa OEM, leliboutu tsa karolo ea merafotšehetsa meralo ea motheo le kholo ea indasteri lefatšeng ka bophara.

Lintlha tsa bohlokoa

- Mekhoa e tsoetseng pele ea ho qhekella e matlafatsa ts'ebeliso ea thepa ho tloha ho 31% ho ea ho 80%, ha e ntse e eketsa matla a bolt le ho tšoarella ka hoo e ka bang 50%.

- Khetho e hlokolosi ea thepa e tala, ho fereka ka nepo, ho thaepa, kalafo ea mocheso, le ho qeta bokaholimo ho netefatsa hore liboutu li kopana ka thata.maemo a boleng le tshebetso.

- Teko e matla le taolo ea boleng e kopantsoeng le liphutheloana tse nepahetseng le thepa ea kantle ho naha e fana ka tiiso ea liboutu tse tšepahalang, tse ka latelloang bakeng sa merero ea lefats'e le merero ea indasteri.

Ts'ebetso ea Tlhahiso ea Bolt e Matla a Phahameng

Khetho ea Matla a Phahameng ea Bolt ea Raw

Baetsi ba qala ts'ebetso ka ho khetha litšepe tsa alloy le lisebelisoa tse ling tse fihlelang maemo a thata a indasteri. Khetho ea thepa e tala e etsa qeto ea matla a sehlahisoa sa ho qetela, ho tšoarella le ho hanyetsa maemo a tikoloho. Hangata baenjiniere ba bolela litšepe tse tlase tsa phosphorus hobane phosphorus e ka baka ho ruruha le ho eketsa kotsi ea ho robeha. Litlaleho tsa indasteri li totobatsa bohlokoa ba dephosphoring, e tlosang phosphorus pele ho phekolo ea mocheso. Mohato ona o thibela ho robeha ha brittle mme o ntlafatsa thepa ea mochini, joalo ka ha ho netefatsoa ke matla a thata le tlhahlobo ea boima. Likhamphani tse kang Ningbo Digtech (YH) Machinery Co., Ltd. mohloli oa tšepe ea boleng bo phahameng ho etsa bonnete ba hore bolt e 'ngoe le e' ngoe e matla e kopana le litlhoko tsa lits'ebetso tsa bohlokoa tsa lits'ebetso le lits'ebetso tsa indasteri.

Hlokomela:Khetho e nepahetseng ea thepa e tala e theha motheo oa liboutu tse tšepahalang, tse sebetsang hantle.

| Mothati oa Ts'ebetso | Tlhaloso & Ntlafatso ea Ts'ebetso |

|---|---|

| Khetho ea Lintho tse tala | Tšebeliso ea litšepe tse khethehileng le li-alloys tse lumellanang le litlhoko tsa kopo ho netefatsa matla le ho tšoarella. |

Ho Etsa le ho Etsa Bolt ea Matla a Phahameng

Ho theha le ho etsa sebopeho sa bolt le ho ntlafatsa thepa ea eona ea mochini. Baetsi ba sebelisa forging e batang bakeng sa liboutu tse nyane ho isa ho tse mahareng, tse eketsang matla ka ho thatafala le ho fana ka ts'ebetso e nepahetseng haholo. Mocheso oa forging o sutu liboutu tse kholoanyane kapa lisebelisoa tse thata ho feta, ho li etsa tse loketseng lits'ebetso tse phahameng haholo. Mekhoa e tsoetseng pele e kang ho phunya le ho taka ka botebo ho ntlafatsa sebopeho sa lijo-thollo, ho ntlafatsa matla le ho hanyetsa mokhathala. Lithuto tsa boenjiniere li bonts'a hore mekhoa ena e boloka thepa le ho eketsa matla ntle le ho itšeha, e bakang liboutu tse nang le bots'epehi bo phahameng ba mochini.

- Ho phunya ho ntlafatsa sebopeho sa lijo-thollo le matla ka kakaretso.

- Ho taka ka botebo le hydroforming ho matlafatsa ho hanyetsa mokhathala le kabo ea khatello ea maikutlo.

- Mekhoa ena e bonahala e sebelisoa liindastering tse kang tsa likoloi, tsa sefofane le tsa kaho.

Ningbo Digtech (YH) Machinery Co.,Ltd. e sebelisa mekhoa ena e tsoetseng pele ea ho qapa ho hlahisaliboutu tse matla haholoe sebetsang ka botshepehi tlasa maemo a hlokang.

Mekhoa e Meholo ea Matla a Phahameng ea Bolt

Khoele e fa liboutu bokhoni ba tsona ba ho tiisa. Baetsi ba sebelisa mekhoa e mengata, e 'ngoe le e' ngoe e na le melemo e ikhethang. Ho roala likhoele ho etsa likhoele ka ho holofatsa thepa, e sebetsang-e thatafatsa bokaholimo le ho hlahisa likhoele tse matla. Mokhoa ona o ratoa bakeng sa litsamaiso tse kholo tsa tlhahiso le boholo ba likhoele tse tloaelehileng. CNC ho sila le ho sila ho fana ka ho nepahala le maemo a holimo, ho etsa hore li tšoanelehe bakeng sa lits'ebetso tse tloaelehileng kapa tse nepahetseng haholo. Mechini ea CNC e iketsetsa ts'ebetso, e fokotsa liphoso tsa batho le ho netefatsa boleng bo tsitsitseng.

| Ntlha | Mochini oa CNC | Traditional Forging/Manual |

|---|---|---|

| Nepahalo | E phahameng haholo, e pheta-pheta boemo ba micrometer | E fapana, ho ipapisitsoe le boits'oaro kapa bokhoni ba opareitara |

| Ho rarahana ha Libopeho | E sebetsana le li-geometri tse rarahaneng, likarolo tsa tloaelo | Molemo ka ho fetisisa bakeng sa libopeho tse bonolo |

| Litšenyehelo tsa ho seta | Mahareng (mochini + lenaneo) | E ka ba e phahameng bakeng sa tloaelo e shoang ka ho forging |

| Lebelo la Tlhahiso | Butle bakeng sa likarolo tse tloaelehileng tsa molumo o phahameng | Ho potlakile haholo haeba libopeho li lumellana (mass forging) |

| Ho tenyetseha | Ho tenyetseha haholo; phetoho e potlakileng | Low flexibility hang ha shoa e etsoa |

| Tšebeliso ea Lintho | E ntle, empa e ka ba le likhechana tse ngata ho feta ho qhekella | Hangata e sebetsa hantle haholo ho qhekella (likhechana tse nyane) |

Keletso:Ho roala likhoele ho eketsa matla a mokhathala le ho ntlafatsa pheletso ea bokaholimo, athe ho seha likhoele ho fana ka meralo e ikhethileng.

Kalafo ea Mocheso oa Bolt ea Matla a Phahameng

Kalafo ea mocheso ke mohato oa bohlokoa o matlafatsang matla a bolt, ho thatafala le ho tsitsa. Mekhoa e kang ho tima, ho futhumatsa, le ho kenya litšepe li lokisa sebopeho sa ka hare sa tšepe. Ho tlosa litšila tse kang phosphorus pele ho phekolo ea mocheso ho bohlokoa, kaha liphuputso li bontša hore karohano ea phosphorus meeling ea lijo-thollo e ka baka ebrittlement le ho robeha tlas'a khatello ea kelello. Kalafo e nepahetseng ea mocheso e tiisa hore bolt e 'ngoe le e' ngoe e matla e ka mamella meroalo e phahameng le libaka tse thata. Mekhoa e meng e tsoetseng pele ea ho theha, e kang ea ho sebelisa tšepe ea twinning-induced plasticity (TWIP), e ka felisa tlhokahalo ea phekolo ea mocheso, ea fokotsa litšenyehelo tsa tlhahiso le linako tsa ho etella pele ha e ntse e finyella thepa e babatsehang ea mechine.

Matla a Phahameng a Bolt a Felletseng

Ho qeta bokaholimo ho sireletsa liboutu hore li se ke tsa bola le ho lelefatsa bophelo ba tsona ba ts'ebeletso. Baetsi ba sebelisa liphahlo tse kang zinc plating, galvanizing, kapa black oxide ho etsa mokoallo khahlanong le mongobo le lik'hemik'hale. Khetho ea ho roala e itšetlehile ka kopo le maemo a tikoloho. Ho qeta bokaholimo ho boetse ho ntlafatsa chebahalo ea bolt mme ho ka ntlafatsa ts'ebetso ea eona libakeng tse ikhethileng. Taolo ea boleng sethaleng sena e kenyelletsa ho hlahloba botenya ba ho roala le ho khomarela ho netefatsa ho tšoarella ha nako e telele.

| Mothati oa Ts'ebetso | Tlhaloso & Ntlafatso ea Ts'ebetso |

|---|---|

| Ho roala ka holim'a metsi | Liaparo tse fapaneng (zinki plating, galvanizing, black oxide) li ntlafatsa ho hanyetsa kutu le ho tšoarella. |

Ningbo Digtech (YH) Machinery Co.,Ltd. e sebelisa mekhoa e tsoetseng pele ea ho qeta holim'a holim'a metsi ho fana ka liboutu tse matla tse finyellang litekanyetso tsa machaba tsa ho hanyetsa kutu le ho tšoarella.

Tiisetso ea Bolt ea Boleng ba Matla a Phahameng le Global Export

Taolo ea Boleng ba Bolt ea Matla a Phahameng le Tlhahlobo

Baetsiitšetleha ka taolo e tiileng ea boleng ho netefatsa hore bolt e 'ngoe le e' ngoe e matla haholo e kopana le maemo a machaba. Ba sebelisa metallurgy e tsoetseng pele le boenjiniere bo nepahetseng ho ntlafatsa matla a bolt le ho tšoarella. Mekhoa ea tlhahlobo ea dijithale le litsamaiso tse ikemetseng tsa taolo ea boleng li lumella licheke tsa nako ea nnete, tse thusang ho fokotsa mefokolo le ho boloka botsitso ba sehlahisoa. Likhamphani tse kang Sinorock li beha mohlala ka ho laola barekisi, ho hlahloba thepa e kenang, le ho netefatsa lihlahisoa tse tsoang. Kgwedi ya bona ya selemo le selemo ya Boleng e kgothalletsa basebetsi ho tsepamisa maikutlo hodima ntlafatso e tswelang pele le temoso ya boleng.

Ho khomarela litekanyetso tse kang ASME B18.2.1, ISO, le ASTM ho netefatsa hore bolt e 'ngoe le e' ngoe ea matla a holimo e finyella litlhoko tse thata tsa boholo, thepa le mochine. Sena se aha tšepo ho bareki ba lefats'e mme se thusa bahlahisi ho hlola mathata a tsoang ho melaoana e fapaneng ea machabeng.

Baetsi ba sebelisa mefuta e mengata ea liteko le litifikeiti ho paka ho ts'epahala ha bolt. Tsena li kenyelletsa:

- Tlhahlobo ea Magnetic Particle ho fumana mapetsong a bokaholimo.

- Projector ea profil bakeng sa licheke tsa boemo ba micron.

- Roughness Tester ho metha bokaholimo.

- Coat Meter ho hlahloba botenya ba ho roala bakeng sa ho hanyetsa kutu.

- Liteko tsa mochini tse kang tensile, mojaro oa bopaki, ho kuta, le torque e teng.

- Liteko tsa metallurgic bakeng sa microstructure le decarburisation.

- Lisetifikeiti tse kang ISO 9001:2015 le tumello ea UKAS.

Mokhoa o felletseng oa tlhahlobo o kenyelletsa tlhahlobo ea pele ea ponahalo, ho lekola boholo, tlhahlobo ea sebopeho sa lik'hemik'hale, tlhahlobo ea matla a thata, le tlhahlobo ea ho hanyetsa kutu. Mehato ena e lebisitse ho theoheng ho hoholo ha litekanyetso tsa ho hloleha ha li-fasteners.

| Mofuta oa Tlhahlobo | Tlhaloso | Maemo / Litifikeiti |

|---|---|---|

| Teko ea Matla a Teko | E lekanya matla a ho tiea a ho qetela, matla a ho hlahisa, ho hola holim'a liboutu tsa boholo bo fapaneng | BS EN ISO 3506-1, BS EN ISO 898-1 |

| Teko ea Boima ba Bopaki | E netefatsa bolt e ka mamella mojaro oa bopaki o boletsoeng ntle le deformation e sa feleng | BS EN ISO 3506-1 |

| Tlhahlobo ea Shear | E lekola khanyetso ea bolt ho matla a ho kuta | ASTM A193, ASTM A194 |

| Teko ea Torque e Atileng | Mehato ea ho hanyetsa ho hlephisa tlas'a thothomelo le khatello ea maikutlo | ISO 2320, BS 4929 |

| Tlhahlobo ea boima | Teko ea ho thatafala ha sefahleho le ea mantlha ho netefatsa matla a thepa | ASTM A194 |

| Sebopeho sa Lik'hemik'hale | Tlhahlobo ea Spark-OES, ICP-OES ho netefatsa litlolo tsa thepa | Mekhoa e netefalitsoeng ea UKAS |

| Teko ea Metallurgical | Microstructure, decarburisation, tlhahlobo ea mekhahlelo, bohloeki ba tšepe | Mekhoa e netefalitsoeng ea UKAS |

| Khanyetso ea Corrosion | Teko ea ho fafatsa letsoai le mongobo ho lekola ho tšoarella ha kalafo ka holim'a metsi | Litekanyetso tse ikhethileng indastering |

| Setifikeiti | ISO 9001:2015, tumello ea UKAS ho ISO/IEC 17025:2017, Nadcap bakeng sa litsamaiso tsa boleng ba sefofane | Litumello tse amoheloang ke machaba le indasteri |

Liteko tsena le litifikeiti li fana ka bopaki bo ka lekanyetsoang ba hore liboutu tse matla a holimo lia tšepahala 'me li se li loketse ho sebelisoa mererong ea sepakapaka, ea nyutlelie, ea leoatleng le ea kaho.

Packaging ea Bolt ea Matla a Phahameng le Thepa ea ho Romela kantle ho naha

Kamora ho fetisa licheke tsohle tsa boleng, bahlahisi ba lokisa liboutu tse matla haholo bakeng sa ho rekisa kantle ho naha. Ho paka ka nepo ho sireletsa liboutu hore li se ke tsa senyeha nakong ea thomello le polokelo. Lik'hamphani li sebelisa mabokose a tiileng, mabokose a lepolanka kapa meropa ea tšepe, ho itšetlehile ka boholo le boima ba thepa. Sephutheloana se seng le se seng se fumana mangolo a hlakileng a nang le lintlha tsa sehlahisoa, linomoro tsa batch, le matšoao a ho latela melao.

Ho paka ka hloko le ho ngola lileibole ho thusa liofisiri tsa lekhetho le bareki ho netefatsa bonnete ba sehlahisoa le ho ba teng ha morao.

Dihlopha tsa thepa e romellwang kantle ho naha di hokahana le bajari ba thepa ba matjhaba ho netefatsa hore ho romelwa thepa ka nako. Ba laola litokomane tsa meetlo, mangolo a mangolo a tlhaho, le mangolo a tumello ea ho romela thepa. Baetsi ba bangata ba sebelisa litsamaiso tsa ho latela tsa dijithale, tse lumellang bareki ho lekola thomello ka nako ea nnete. Ho kopanngoa ha IoT le ho hlokomeloa esale pele tlhahisong ho tšehetsa boleng bo tsitsitseng, ho etsa bonnete ba hore thomello e 'ngoe le e 'ngoe ea matla a holimo e finyella litlhoko tsa bareki ba lefats'e.

Baetsi ba latelang mehato ena ba boloka botumo bo matla 'marakeng oa lefatše. Boitlamo ba bona ba netefatso ea boleng le thepa e tšepahalang bo netefatsa seoliboutu tse matla haholofihla ka polokeho mme o sebetse ka moo ho lebelletsoeng libakeng tse boima.

Mothati o mong le o mong oa tlhahiso ea matla a phahameng a bolt, ho tloha ho forging ho ea kantle ho naha, o ts'ehetsa polokeho le ts'ebetso. The Fastener Quality Act le litekanyetso tsa machaba tse kang ISO 898-1 le ASTM F568M li netefatsa taolo e tiileng ea boleng. Bareki le baenjiniere ba tšepa lits'ebetso tsena ho fana ka litharollo tse tšepahalang tsa bolt tse matla bakeng sa merero ea bohlokoa.

LBH

Ke liindasteri life tse sebelisang liboutu tse matla haholo?

Liboutu tse matla haholoho tšehetsa merero ea kaho, ea likoloi, ea matla, le ea meralo ea motheo. Liboutu tsena li fana ka likhokahano tse tšepahalang marokhong, meahong, metjhini e boima le li-turbine tsa moea.

Baetsi ba etsa bonnete ba boleng ba bolt joang?

Baetsi ba sebelisa liteko tse thata, ho kenyeletsoa ho tiea, ho thatafala le ho chekoa ha kutu. Ba latela litekanyetso tsa ISO le ASTM. Litlhahlobo tsa dijithale li thusa ho boloka boleng bo tsitsitseng.

Ke sephutheloana sefe se sireletsang liboutu nakong ea ho romelloa kantle?

- Mabokose a tiileng

- Likerese tsa lehong

- Meropa ea tšepe

Sephutheloana se seng le se seng se na le lileibole tse hlakileng, linomoro tsa batch, le matšoao a ho latela melao bakeng sa thomello e bolokehileng, e ka lateloang.

Nako ea poso: Jul-09-2025